Turning and milling operations

Токарные и фрезерные работы

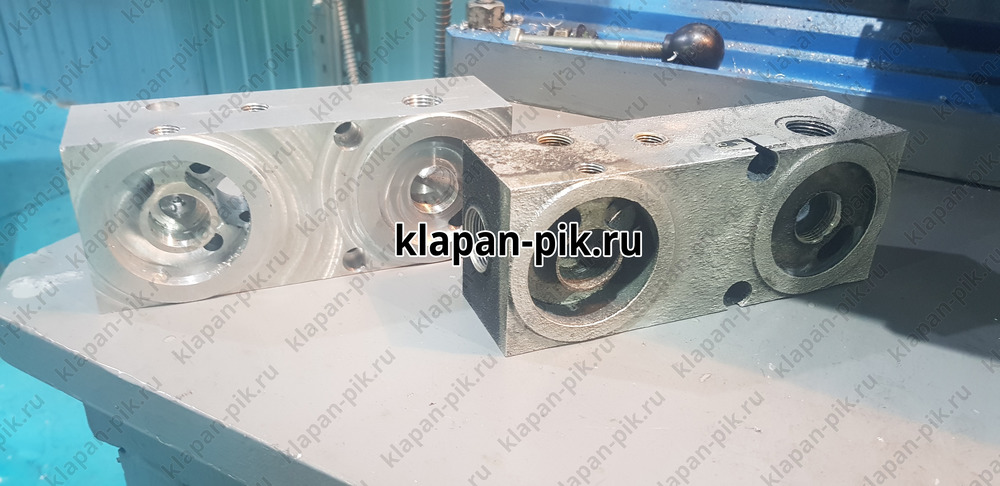

Токарно-фрезерные работы - это техническое изменение геометрической формы и размеров заготовки. Они позволяют изготавливать широкий ассортимент деталей: валы, фланцы, кольца, изделия по Вашим чертежам и т. д.

Наша компания предоставляет:

- Фрезерование и шлифование головок цилиндров двигателей внутреннего сгорания;

- мойка блоков цилиндров в ультразвуковой ванне;

- выполняем заточку деталей;

- резка на ленточной пиле;

- выполняется снятие фаски;

- литье цветных металлов в формы под давлением до 380 атмосфер;

- выполните обрезку и развертывание заготовок;

- обработка поверхностей деталей;

- выполнение зенковки, облицовки, расточки;

- создание деталей со сложной геометрией.

Технология универсальна и позволяет работать с любыми черными и цветными металлами, а также с их сплавами.

Make:

- valves for reciprocating compressors;

- shafts;

- stock;

- pulleys;

- gaskets for any purpose (paranite, aluminum);

- lubricators;

- fasteners;

- cylinders;

- Pistons;

- fittings;

- hydraulic spare parts;

- products according to the customer's drawings.

At the same time, we guarantee the quality of products and undertake to fulfill the order within the agreed time frame.

Остались вопросы? — Напишите нам!

Send an application

Clients of the company "Compressor technology" can get personal consultation about products, and full information about the installation, commissioning and maintenance. The company's policy "Compressor Technology" is aimed solely at long-term relationships with our clients. In our opinion this is the key to success.