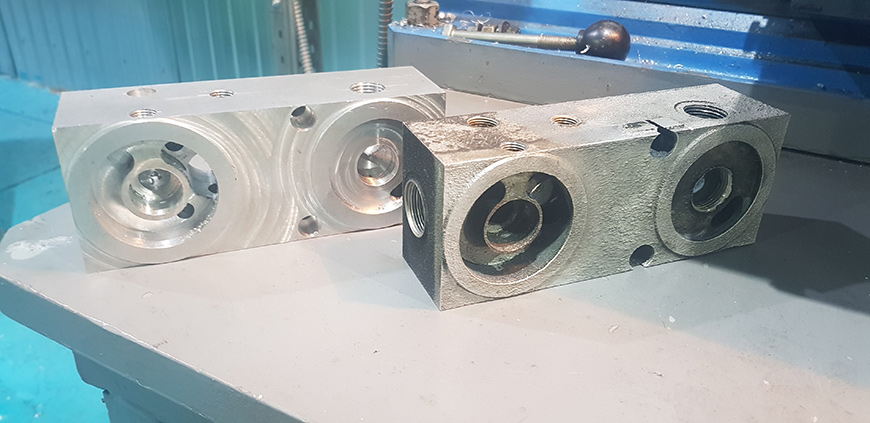

Aluminum die casting

Die casting of aluminum is a high-precision technology for the production of products, during which an aluminum alloy fills a mold and takes the form of a casting. Due to the plasticity of the metal and high pressure, it is possible to manufacture parts with a thickness of 0.5 mm, with 2 cavities in different projections and internal or external threads. This casting method is widely used in the automotive, plumbing, instrumentation, shipbuilding and many other industries. The final products can weigh from a few grams to several kilograms. The condition for high quality is a high-quality form (chill mold) and a competent performer (plant). The cost of making the mold is compensated by the high quality of the products and the minimum yield of defects.

Technical process of aluminum die casting

- Mold opening and lubrication. This stage is necessary so that the metal does not freeze in the mold during casting, and also so that the finished product is easily detached from the mold at the end of the process.

- Closing the mold. The characteristic of the clamping force of the mold is what gives the name to the equipment. For example, if a casting machine has the number 300 in its name, this means that its clamping force is 3000 kilo-Newtons or 300 tons. That is, such a machine will be able to hold back the metal that seeks to open the 300-ton mold.

- Pouring aluminum into the bale chamber.

- Pressure pressing process.

- Withdrawal of the finished product.

Advantages of the aluminum die casting method

- High dimensional accuracy of the finished product (3-7 accuracy classes)

- Good surface quality of castings, minimal roughness

- Low porosity of the finished casting

- Minimal or no mechanical post-processing required

- The ability to easily set up the release of both a one-time limited batch, and set up a production process

- High production speed

The Compressor Technologies company has been casting aluminum and other metals for over 9 years. We take in work drawings of customers of varying complexity and guarantee the execution of the order under the contract and on time.

Остались вопросы? — Напишите нам!

Send an application

Clients of the company "Compressor technology" can get personal consultation about products, and full information about the installation, commissioning and maintenance. The company's policy "Compressor Technology" is aimed solely at long-term relationships with our clients. In our opinion this is the key to success.